Using a hand plane

Posted on December 14, 2019 by admin

Woodworkers are always learning

We learn from our own experience, we learn by networking with other woodworkers, Every one has favorite tools and favorite methods, hacks and shortcuts. I have used a plane or two for many years and I confess, I learned a lot of things I didn’t know about the hand plane while researching and writing this article.

Woodworking is more than just knowing and having the right tool, as important as that is. Woodworking is problem solving. It is fun and challenging. And a finished product can be very rewarding.

Enjoy Using a bench plane

The direction of your material is important, going “against the grain” will result in tear out and jam ups. Plane with the grain in the direction the grain is rising or bows up looking from the end of the material. It can also change along a longer piece so sometimes you may have to change direction or go from ends to center or from center to ends.

Extra woodworking tip: If you are joining pieces of wood that you plan on surfacing later, pay attention to keep the grain going in the same direction.

Material can be twisted, warped, bowed or cupped. That is often why we need to plane it, to true it up.

Basic types of hand planes.

Let’s define the basic types of hand planes so that we understand the difference. Hand plane includes all types as opposed to a power planer which we will cover on another page.

Bench plane,

Jack Plane,

Scrub Plane

Smoothing plane,

Block Plane,

Rabbit Plane.

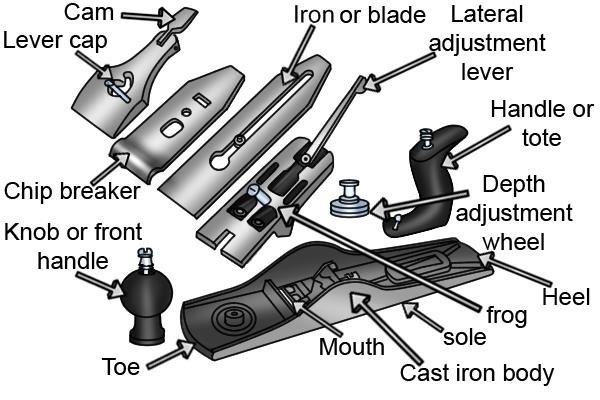

First, the parts of a bench plane, and assembly. A good quality hand plane is a fairly complicated device because to work properly it requires a lot of precise adjustments. Edge angle and angle of the blade, depth of cut, lateral angle, and where the chip breaker is positioned are all important to the use and function. Once the adjustments are correct everything has to be solidly secured to take a tremendous amount of pressure.

Heel and Toe

Blade or Iron

Frog with lateral adjustment

Lever Cap with cam

Cap Iron

Chip Breaker

Mouth

Sole

Knob

Handle

Bevel up planes vs. bevel down planes.

The bevel is the sharpened surface of the blade, usually around a 25 degree angle. The bevel up blade is changed by the angle at which the bevel is honed The advantage of a bevel up plane is it does not use as many parts, with no chipbreaker or lateral adjustment lever. It is probably not as effective as a bevel down smoothing plane for larger surfaces. It is easier to make adjustments, but doesn’t allow for as much precision in the set up.

Bench Plane

Stanley numbering system. For basic bench planes, 1 is the smallest, 8 is the largest. Actually the #1 Sweetheart is an exception because it means the first model Stanley made. It is an antique and can often sell for over $1500. (see it on EBay)

1 – Block plane #2 #60 1/2 (Meaning 6 1/2 inches long)

2 – Smoother – #3 to #5 1/2

3 – Jointer – #7 – #8

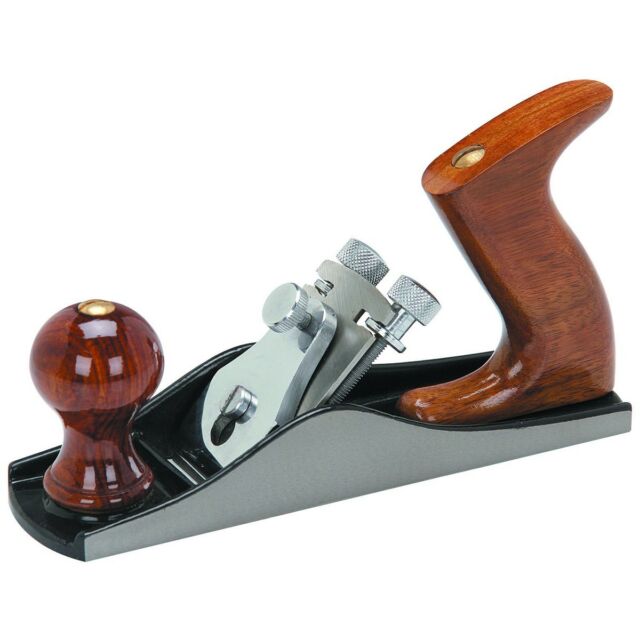

This Windsor Design bench plane has a rugged high carbon steel cutter for general purpose work. The cutter is easily adjusted for depth of cut.

I got mine from Harbor Freight for $14 but the workmanship of this tool left a lot to be desired. The chip breaker is too far from the cutting edge adjusted all the way in. Both of the depth adjustment knobs were too far from the blade to even be effective. I had to decide whether to return it or try to McGuiver it myself by grinding the surface down or putting a washer in the slot. To adjust the lever cap would require a longer slot.

Jack Plane #51/2 14 inch

Low angle jack planes Using a jack plane

A 9 inch smoother, The Stanley #4 is faster and easier to use than sandpaper, and leaves a nice smooth finish.

Smoothing Plane with smooth foot.

Smoothing #7 Fore Plane #6

The smoothing plane is usually longer (18 inches) and often has a grooved foot. It is used more for surfacing a larger flat area. This requires a finer sharpened edge and more precise adjustments for depth. When smoothing the plane should be used at about a 30 to 45 degree angle to the wood to get a wider “read” rather than working with the tool straight on.

Add degrees of blade angle for more difficult or harder woods. Steeper cutting angles (50 degrees) cut better without tear out on difficult grain.

Block Plane

Rabbit Plane

Bull Nose

Also known by Shoulder, Chisel, Bull Nose, Rebate

A low angle block is best for trimming end grain.

Rabbit plane, is best to clean up dadoes and grooves.

A regular block plane for breaking edges and general purpose and reduces the need for sanding.

No. 40-1/2 Scrub Plane

Not as popularly well-known, and probably often had it’s function religated to what was on hand is the Scrub Plane.

A scrub plane is designed to remove large quantities of wood. Based on the Stanley 40 1/2, the open throat and curved blade allow you to take deep cuts. Used diagonally or at about 45 degrees to the wood surface the Scrub Plane can quickly thickness rough sawn boards or cut stock to width before following with a Jack or Smoothing Plane.

It has a rounded down bevel. It’s a great tool for shaping irregular objects, backing out molding for irregular walls, or producing a textured surface.

- 10-1/4″ long. 3″ Blade radius. Iron body, 2.40 lbs.

Ironically you can buy a Power hand planer for about the same money as a good hand plane. We will cover that more expressly in a power tool page.

Tips on how to use a hand plane.

First make sure your material is clamped in a vice or secured and shimmed securely so it can’t rock, slide or move. You can also put it against a table block. The plane has two handles for a reason. To use it correctly it is a two hand job. (Making an exception for the small block plane) You will need to be lined up straight with your work, even though you may sometimes angle the plane to facilitate the slicing cutting edge and to get a better read on wider stock.

I do a lot of work with reclaimed wood so I always want to go over the material extremely carefully to make sure I don’t hit anything like nails, screws, staples or even dirt and rocks that might nick the blade. Those damn nicks will make a smooth surface impossible and they are hard to sharpen out of the blade. Double check that.

Next I want to scribe carefully and accurately on both sides to where I want my surface to finish out. Then bevel the corners to the marked line. To plane the surface, I use a straight edge like a tri-square to check for flat and true and plane flat until the bevel is gone. This makes it simple to see where you need to cut.

Beveling the corners will also prevent splintering and tear out on the corners, which is a common problem without doing that first.

Sometimes if its hard to tell then rub some pencil lead or chalk on a flat paint stick and rub it across. That will leave residue where you need to plane. You can also use another flat surface to check to see where light comes through on the low points.

Some common mistakes using a plane.

Not securing the work piece properly

Setting the blade too aggressively

Not having a sharp blade.

Working against the grain.

Plain Plane Fun

It is always fun to see those shavings coming off in perfectly uniform curled thin ribbons. That is an indication that your tool is set and sharpened correctly. The plane and the handsaw (which will be another post soon) are the basic tools of the “Hand tool only” woodworking purist. Most people now days however use their hand tools in conjunction with power tools. Especially since the advent and popularity of all the new fantastic cordless battery powered arsenal.

Hand Made Wood Plane.

The beautiful hand made plane, from birch and rosewood, at the top of the page is a work of art. I can’t imagine trying to actually use that for the kind of work I do. If I owned that I would set it on my mantel for a conversation piece. I think the joy of that was in the making, not the using.

Sharpening hand plane

cheap block plane 24 127

cheap bench plane 40 41

Plane blade sharpening angle should be about 25 degrees.

Rob Cosman can explain it faster and better than I ever could.

plane blade sharpening stone 32 78

It may be a good idea to clamp your blade to wood block jig fashioned so that that holds it at the correct angle. It’s difficult without experience sometimes to hold it at the precise angle to do freehand sharpening.

Trust Your Judgment on what is Quality.